What technology do I need to measure the efficiency of my packaging manufacturing lines automatically?

SCADA?

For many people, SCADA (Supervisory, Control and Data Acquisition System) is the first kind of system that comes to mind when thinking about a shop floor software. And indeed SCADA systems are quite flexible and therefore can supply custom demands a manufacturing plant.

But when talking about OEE (Overall Equipment Efficiency – see more here ), there are several key points to have in mind. OEE is strongly dependent on counters and unlike other time-series variables such as temperature and speed, counters only make sense when you consider the value within a time-frame. Usually it will be shift, day, week and jobs. So analysing performance of a job means aggregate the counter increment within the job period. And there are several other characteristics that add complexity to the case:

- when is counter reset on the PLC?

- How to get a fast query response of total production during a shift if the counter was reset during this period?

- How to get quick response on reports for longer periods, such as month to month?

The challenge is no longer on how many tags and displays the SCADA will need. There is a lot of background processing involved and a good knowledge on database systems. So, SCADA can handle the job, but the customization might take much longer than the alternative solution.

MES?

And then come MES systems. MES stands for Manufacturing Execution System. In short, it is a system to monitor the performance of assets, relying on sensor data collection and a powerful database engine.

According to Gartner’s Magic Quadrant for Manufacturing Execution Systems (2018), a MES must have at least the following core functionalities:

- Dispatching – ability to dispatch jobs according to instructions from ERP

- Production management, execution and in-process quality monitoring — Managing the production process from order release to work in process (WIP) to finished goods

- Data collection – ability to collect data from the end user at a defined interval, or automatic directly from the machine, or a combination of both

- Operational data store – the database engine that will store the collected data and power the custom reports

- Manufacturing-related quality management processes — For regulated environments, where corrective and preventive action (CAPA) and nonconformance workflows are required to be inextricably linked to the production process

- Procedural enforcement – ensure that all manufacturing steps are performed in the correct order

- Tracking and genealogy – ability to track where each is in the production process as well as the source of components, equipment and personnel, according to the industry regulatory needs

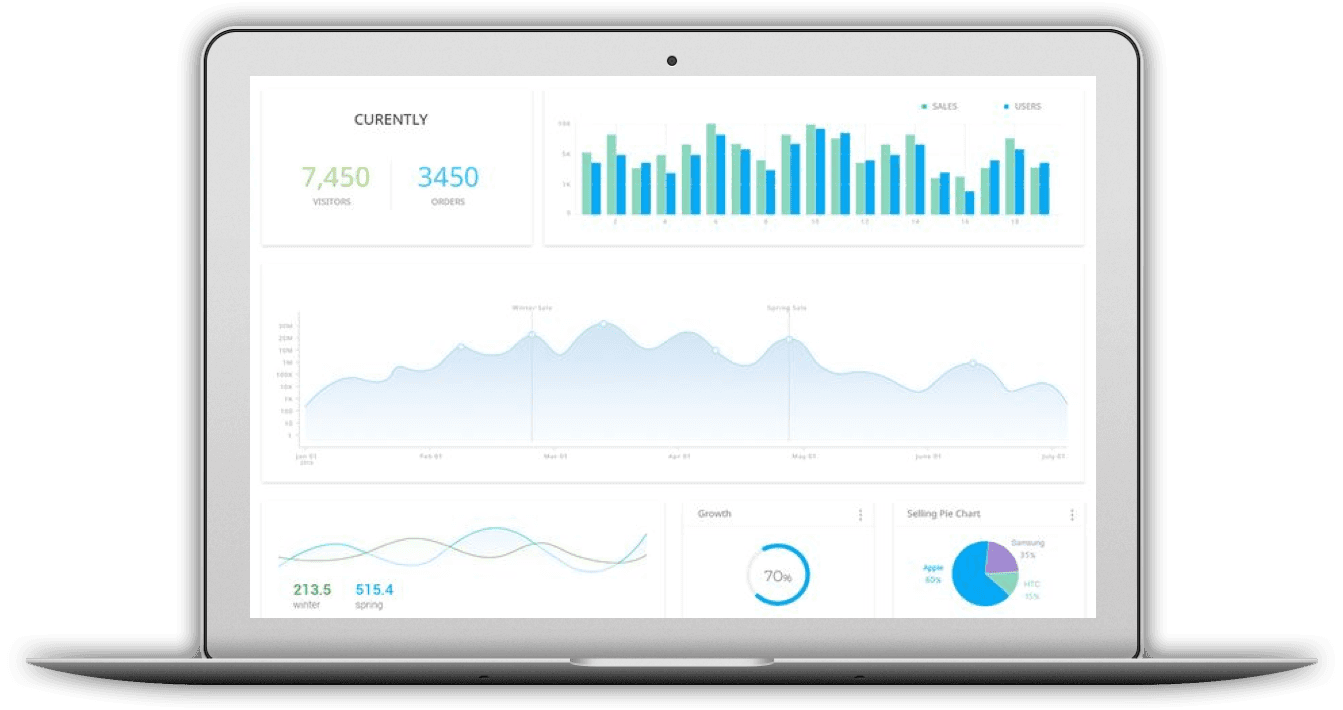

- Integrated reporting and plant key performance indicators (KPIs) — Tools and techniques for generating KPI results, performing advanced analytics, and providing dashboard displays and datasets for performance monitoring and reporting

With such an importance that range from data collection to quality, traceability and business intelligence, a MES is a complete software that for some cases might provide much more than the company needs, and therefore, is presented with a longer customization and a ROI higher than expected. What happens in most cases is that the implementation fails due to high complexity: a system that can do everything might end up doing nothing at all, while sunk costs rise and rise, as nicely described in this blog post by McKinsey.

If performance is the key demand, what solution will bring the most favorable ROI?

With technologies that recently emerged from IoT needs, a new horizon of solutions is rising, providing better ROI for specific needs. Open-source data collectors running on fanless computers provide a great cost-benefit for this layer, while a cloud BI platform leverage database data, empowering managers and maintenance teams on a pay per user contract.

The rise of IIoT platforms allow for rapid prototyping of custom solutions, requiring a shorter upfront investment while increasing reliability and security on the architecture. But still, generic IIoT platforms will have a learning curve, development time and maintenance of the system.

So, what is the road to happiness?

Purpose specific IIoT platforms, on the other hand, provide a framework that tends to be much closer to what most plant demands, which includes reports tailored for the niche as well as the data preparation necessary. As mentioned before, the value of a counter on a given time is not as simple to retrieve as a room temperature for the same time. There is a lot of context involved, which requires a custom tailored database model and data preparation. And even with all the reports specific for the niche market, enterprise software always requires customization.

There will always be a need for custom reports to meet the demand of keyholders, as well as custom integration with ERP, so it is important that the IIoT platform allows integration with Business Intelligence systems and is not closed to integrations. Systems can no longer work as data silos, so with custom integrations comes also the need for the platform to be always up-to-date with recent technologies.

With BIs and ERPs launching new version releases every quarter, is your OEE system also evolving together? A simple API security change on an ERP can turn an integrated OEE system into a legacy one, so in this sense, a Software as a Service might be more suitable than a one time payment licensing model as future integration demands might require a complete new software version and deployment.

For every application there is a most suitable solution, but one thing is for sure: no decision should be made before having a look into modern IIoT technologies.

*PackIOT is an IIoT platform for the packaging industry. From data collection to KPIs, we provide a complete and managed solution ready to be used on the shop floor or anywhere with mobile interface.